Electronic drum pads, devices offering versatility and quiet practice, exhibit increasing popularity among drummers and music producers alike.

These sophisticated percussion instruments integrate sensitive electronic components, making their proper care and long-term storage paramount for preserving functionality and extending operational lifespan.

Neglecting appropriate storage protocols often results in irreversible damage, diminished performance, or complete equipment failure, thereby compromising the significant financial and creative investment users make.

This comprehensive guide systematically explores crucial aspects of electronic drum pad storage, dissecting pre-storage preparation, ideal environmental conditions, and ongoing maintenance practices.

Readers will gain invaluable insights into preparing their drum pad module and percussion pads for extended dormancy, identifying optimal storage locations, and understanding the necessary periodic checks required to safeguard their electronic drum kit.

The article aims to empower users with the knowledge essential for protecting their valuable musical equipment and ensuring its pristine condition for future musical endeavors.

Why Proper Long-Term Storage Matters

Proper long-term storage primarily safeguards electronic drum pads from a multitude of potential harms, encompassing physical, environmental, and biological threats.

This meticulous approach ensures the preservation of the instrument’s structural integrity and operational capabilities, preventing issues that might otherwise necessitate costly repairs or premature replacement.

An inadequate storage environment or insufficient preparation directly compromises the delicate internal circuitry and external materials that comprise these intricate devices.

Protection from Damage

Protecting your electronic drum pad from damage represents a foundational benefit of proper long-term storage.

Physical damage, such as scratches, dents, or cracks, frequently occurs when pads lack adequate cushioning or are stored in precarious positions where impact is likely.

Environmental damage, including exposure to excessive humidity or extreme temperatures, causes detrimental effects on sensitive electronic components, rubber pads, and even the plastic casing of the drum pads.

Moreover, long periods of inactivity in unsecured locations often invite pest infestation, leading to gnawing on wires or nesting within internal cavities, which constitutes a significant threat to device integrity.

Preservation of Functionality

Preserving the functionality of your electronic drum pad during extended periods of disuse requires meticulous attention to storage conditions.

The intricate network of sensors, piezo elements, wiring harnesses, and integrated circuit boards within each pad and the drum module itself remains highly susceptible to degradation from adverse environmental factors.

For instance, prolonged exposure to high humidity fosters corrosion on metallic contacts and solder joints, impeding signal transmission and leading to intermittent or complete failure of triggers.

Similarly, temperature fluctuations induce material expansion and contraction, potentially loosening connections or stressing delicate electronic circuits, thereby compromising the pad’s responsiveness and overall performance reliability.

Proper storage safeguards these critical components, ensuring trigger sensitivity and MIDI output remain consistent upon retrieval.

Maximizing Lifespan

Maximizing the lifespan of your electronic drum pad directly correlates with the quality of its long-term storage.

Each electronic instrument possesses an inherent operational longevity, which meticulous care and protection significantly extend.

By mitigating exposure to harmful elements like dust accumulation, moisture ingress, and physical impact, owners reduce the likelihood of premature wear and tear on both internal electronics and external playing surfaces.

This proactive approach translates into substantial savings by circumventing the need for frequent repairs, component replacements, or the ultimate necessity of purchasing an entirely new drum pad unit.

Investing time in proper storage thereby becomes an investment in the enduring utility and value of your musical equipment.

Maintaining Resale Value

Maintaining a high resale value for your electronic drum pad intrinsically links to its preserved physical and functional condition through proper storage.

A well-maintained instrument, free from visible damage, internal malfunctions, or signs of environmental degradation, commands a significantly higher price in the secondary market.

Buyers often prioritize electronic drum kits that demonstrate meticulous care, recognizing that such units promise reliable performance and extended utility.

Documentation of proper storage practices, such as storing in original packaging or dedicated hard cases, further enhances perceived value.

Conversely, neglected pads exhibiting cosmetic blemishes, corroded ports, or intermittent triggers inevitably suffer substantial depreciation, reflecting the anticipated repair costs or performance compromises.

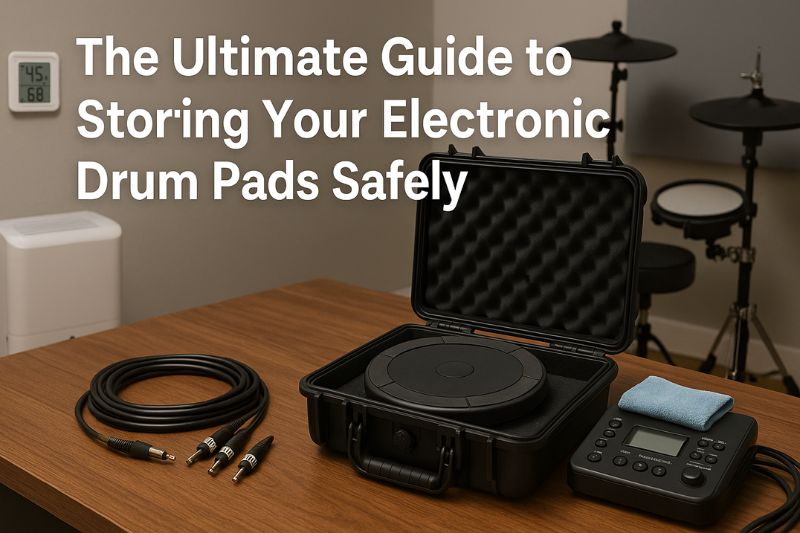

Pre-Storage Preparation: A Step-by-Step Guide

Thorough pre-storage preparation systematically addresses potential issues that might arise during the electronic drum pad’s dormancy, thereby preventing degradation and ensuring its readiness for future use.

This crucial phase involves a series of detailed steps designed to clean, secure, and organize the components of your electronic percussion instrument before it enters long-term storage.

Each action taken during this preparatory stage contributes directly to the longevity and functional integrity of the device.

Cleaning Your Drum Pad Thoroughly

Cleaning your electronic drum pad thoroughly prior to storage eradicates accumulated grime and residues, which, if left untreated, could cause long-term damage or attract pests.

Dust, skin oils, and perspiration frequently settle on rubber playing surfaces, plastic casings, and within crevices around trigger zones.

Over time, these substances can degrade materials, foster the growth of mold or mildew in humid conditions, or even seep into sensitive areas, compromising internal electronics.

A comprehensive cleaning protocol thus safeguards the material integrity and aesthetic appeal of the percussion pads and their accompanying module.

To effectively clean surfaces, users should first gently wipe down all exterior surfaces of the electronic drum pad and any associated drum module with a soft, lint-free cloth.

For stubborn smudges or light dirt, the cloth may be ever so slightly dampened with plain water, ensuring no excess moisture remains.

Specialized electronic cleaning wipes, free of harsh abrasives or solvents, also represent an excellent option, as they are formulated to be safe for sensitive electronic equipment.

It is imperative to avoid the application of abrasive cleaners, alcohol-based solutions, or strong chemical solvents, as these agents can damage rubber compounds, degrade plastic finishes, or even corrode metallic components.

For intricate areas and crevices, such as around MIDI ports or under pad rims, a soft-bristled brush or compressed air can effectively dislodge dust and small debris without causing harm.

This meticulous cleaning procedure forms the cornerstone of proper storage, preventing the insidious effects of environmental contaminants.

Disconnecting and Organizing Cables

Disconnecting and organizing all associated cables represents a critical step in preparing your electronic drum pad for long-term storage, preventing cable damage and facilitating easy reassembly.

Leaving cables connected can strain ports, lead to kinks or frays in the cabling itself, or even induce electromagnetic interference if other devices are nearby.

Proper cable management minimizes physical stress on both the cables and the audio jacks, MIDI ports, and power inputs of the drum module and individual percussion pads.

Moreover, systematically labeled and neatly coiled cables significantly streamline the setup process when the time comes to retrieve and reconnect your electronic drum kit.

Users should carefully disconnect every cable attached to the electronic drum pad and module, including audio cables (e.g., 1/4″ instrument cables), MIDI cables, and the power supply unit.

Avoid yanking on cables; instead, gently pull the connector head itself to prevent strain on the cable’s internal wiring or the port’s integrity.

Once disconnected, each cable type should be clearly labeled, perhaps using cable ties with written tags or color-coding, indicating its function (e.g., “Pad 1 to Module,” “Main Out L,” “Power”).

This labeling system eradicates confusion during reassembly, especially crucial for complex multi-pad setups.

Finally, neatly coil each cable, following its natural curve to prevent kinking, and secure it with reusable Velcro cable ties or specialized cable wraps.

Storing these organized cables either in a dedicated compartment within the drum pad case or in a separate, clearly marked bag ensures they remain protected and readily accessible.

Removing Batteries (If Applicable)

Removing all batteries from your electronic drum pad or module (if it features battery compartments) constitutes an indispensable preventative measure against battery leakage and subsequent corrosion.

Batteries, particularly alkaline types, possess an inherent tendency to leak corrosive fluids over time, especially during prolonged periods of inactivity or when exposed to temperature fluctuations.

This leaked fluid, a caustic electrolyte, directly damages battery contacts, internal circuitry, and even the surrounding plastic housing of the electronic device, often resulting in irreparable harm.

The process involves opening any battery compartments, carefully extracting all batteries, and then properly disposing of them according to local environmental regulations.

Users should inspect the battery compartment for any pre-existing signs of leakage or corrosion buildup; if present, a cotton swab lightly moistened with isopropyl alcohol can gently clean affected terminals (ensure the device is completely dry before proceeding).

It is critical to store any empty battery compartments in a dry, room-temperature environment.

This simple yet vital step completely eliminates the risk of internal damage from corrosive battery fluids, thereby safeguarding the sensitive electronic components and ensuring the long-term operational integrity of your drum pad module.

Disassembling Components (Optional but Recommended for Compact Storage)

Disassembling certain modular components of your electronic drum pad system, while optional, often provides significant benefits in terms of compact storage and enhanced protection during transit or long-term dormancy.

Many electronic drum kits feature detachable pad towers, cymbal arms, or even individual percussion pads that connect via simple mounting mechanisms.

Deconstructing the setup reduces its overall footprint, allowing for more efficient use of storage space and fitting into smaller protective cases.

Moreover, separating components can minimize stress points that might occur if the entire assembled unit were stored in a confined space, reducing the risk of bending, warping, or snapping delicate parts.

Users considering disassembly should always consult the manufacturer’s manual for their specific electronic drum pad model.

This manual provides precise instructions regarding which components are designed for detachment, the correct tools required (if any), and the proper sequence for safe removal.

As components are separated, it is absolutely essential to keep all small parts, such as screws, washers, mounting clamps, or drum key bolts, organized in clearly labeled, sealed bags.

For example, a bag labeled “Module Mounting Screws” prevents frustration and loss during reassembly.

Proper labeling ensures that every piece can be reunited with its correct counterpart, facilitating a smooth and accurate setup process when the electronic drum kit is retrieved from storage.

This meticulous approach to disassembly and organization directly contributes to the overall safety and future usability of the instrument.

Original Packaging vs. Aftermarket Cases

Choosing between original packaging and aftermarket protective cases represents a crucial decision for safeguarding your electronic drum pad during long-term storage, each offering distinct advantages and levels of protection.

The original box and its internal foam inserts, if still available, often provide an excellent solution because they are custom-designed by the manufacturer to fit the specific contours of the drum pad perfectly.

This tailored fit minimizes movement within the packaging, thereby reducing the risk of impact damage or abrasion during handling.

However, original cardboard boxes may lack durability against environmental factors like moisture or extreme pressure from stacking.

Conversely, aftermarket padded gig bags or robust hard cases offer superior protection, often designed for musicians who frequently transport their gear.

A padded gig bag, typically constructed from durable fabric with thick foam padding, offers excellent shock absorption against minor impacts and protection from dust and scratches.

These are lighter and more portable than hard cases.

For ultimate protection against severe impact, crushing, moisture ingress, and even extreme temperature fluctuations, a hard case made from rugged plastics or reinforced composites with custom foam cutouts is unparalleled.

Hard cases often feature water-resistant seals and reinforced corners, making them ideal for long-term storage in less than ideal environments.

While a hard case represents a greater initial investment, it significantly extends the lifespan and maintains the pristine condition of your electronic drum pad, thus justifying the cost for valuable musical equipment.

In situations where original packaging or dedicated cases are unavailable, users can improvise protection using layers of bubble wrap, soft blankets, or towels to cushion the pad within a sturdy plastic container, ensuring all surfaces are covered and movement is minimized.

Choosing the Right Storage Location

Selecting the appropriate storage location represents a paramount decision for the long-term preservation of your electronic drum pad, as the ambient environment directly impacts the integrity of its sensitive components.

An ideal storage setting mitigates risks associated with temperature extremes, uncontrolled humidity, and exposure to direct sunlight or pests.

The physical attributes of the storage space profoundly influence the longevity and functionality of the stored electronic instrument, making careful consideration essential.

Temperature and Humidity Control

Maintaining precise temperature and humidity control within the storage environment is critically important for the long-term health of your electronic drum pad.

Electronic components, rubber playing surfaces, and plastic casings are highly susceptible to damage from fluctuating conditions.

Ideal storage conditions dictate a stable, moderate temperature range, typically between 18-25°C (65-77°F).

Temperatures significantly above this range can accelerate the degradation of electronic circuitry, cause adhesives to weaken, or lead to the warping of plastic parts.

Conversely, excessively cold temperatures can make materials brittle, potentially leading to cracking and fostering condensation formation as temperatures fluctuate.

Humidity management is equally vital: high humidity levels (above 60%) introduce the pervasive threat of moisture ingress, which directly causes corrosion on metallic contacts, solder joints, and even circuit board traces.

Prolonged dampness also encourages the growth of mold and mildew on non-metallic surfaces, leading to unpleasant odors and material degradation.

Conversely, extremely low humidity (below 30%) can cause rubber pads and other composite materials to dry out, leading to cracking and reduced elasticity over time.

To counteract humidity, desiccants (e.g., silica gel packets) placed within the protective case or storage container can absorb excess moisture.

In larger storage areas, a dehumidifier or humidifier might be necessary to maintain optimal levels.

Continuous monitoring with a simple hygrometer provides real-time data, allowing users to proactively adjust the environment and safeguard their percussion pads and drum module from insidious environmental damage.

| Environmental Factor | Ideal Range | Risk of Extremes (High) | Risk of Extremes (Low) | Mitigation Strategies |

|---|---|---|---|---|

| Temperature | 18-25°C (65-77°F) | Component degradation, adhesive weakening, plastic warping | Material brittleness, cracking, condensation issues | Climate-controlled rooms, insulated storage |

| Humidity | 40-60% | Corrosion, mold/mildew growth, material swelling | Drying out of materials, cracking of rubber/plastic | Desiccants, dehumidifiers/humidifiers, sealed containers |

| Light Exposure | Dark | UV degradation, color fading | N/A (no negative effects) | Opaque covers, dark storage areas |

Avoiding Direct Sunlight and Pests

Avoiding direct sunlight and preventing pest intrusion are two critical considerations for preserving the long-term integrity of your electronic drum pad.

Direct sunlight, specifically its ultraviolet (UV) component, inflicts significant damage on various materials found in electronic musical instruments.

Prolonged UV exposure causes plastic components to become brittle and discolored, leading to fading of colors and accelerated material degradation.

Furthermore, UV radiation can heat the surface of the drum pad, contributing to localized temperature extremes that stress internal electronic circuitry and adhesives.

Therefore, storing the instrument in a dark environment or under an opaque cover is highly advisable.

Pest prevention safeguards against biological threats that can cause physical damage and hygiene issues.

Rodents, such as mice and rats, often chew through power cables, MIDI cables, and even internal wiring harnesses to construct nests or sharpen their teeth, resulting in severe functional damage to the drum pad module and percussion pads.

Insects, including cockroaches and silverfish, can infest electronics, leaving behind corrosive droppings or damaging sensitive connections.

Maintaining a clean and sealed storage area effectively deters these unwelcome invaders.

This includes using airtight storage containers or hard cases to create a physical barrier and ensuring the general storage environment remains free of food crumbs or other attractants.

Regular inspection of the storage area and the drum pad itself can identify early signs of pest activity, allowing for prompt intervention before extensive damage occurs.

Recommended Storage Locations

Selecting recommended storage locations for your electronic drum pad involves assessing environmental stability, security, and accessibility, ensuring the instrument’s sustained protection.

Different locations offer varying degrees of suitability, ranging from highly controlled professional spaces to more common household environments.

The choice of location significantly impacts the effectiveness of long-term preservation efforts.

- Climate-Controlled Storage Unit: A climate-controlled storage unit represents the most ideal, albeit often the most costly, solution for long-term storage of sensitive electronic equipment.

These facilities maintain consistent temperature and humidity levels year-round, specifically designed to protect items from environmental extremes that cause material degradation, corrosion, or electronic malfunction.

Their robust security measures also provide excellent protection against theft and unauthorized access.

While economically demanding, this option offers unparalleled peace of mind for valuable electronic drum kits. - Spare Room or Closet: A spare room or an internal closet within a residence frequently offers a suitable environment if general household conditions are stable.

These indoor locations typically experience fewer temperature fluctuations and better humidity control compared to garages or attics.

Positioning the drum pad away from exterior walls, windows, and direct heat sources (e.g., radiators, vents) further enhances stability.

Adequate ventilation within the closet or room also prevents stale air and potential moisture buildup.

This option combines convenience with reasonable protective capabilities for moderate-term storage. - Under a Bed: Storing an electronic drum pad under a bed can function as a viable option for compact and short-to-medium term storage, provided the area remains clean, dry, and free from significant dust accumulation or temperature shifts.

The space under a bed typically benefits from the general climate control of the bedroom, offering a degree of stability.

However, it is paramount to place the drum pad inside a well-sealed protective case or an airtight plastic container to shield it from dust, potential spills, and accidental impacts.

Without adequate sealing, dust can infiltrate sensitive components, leading to operational issues upon retrieval. - Attics or Basements (Generally Not Recommended): Attics and basements are generally not recommended as long-term storage locations for electronic drum pads due to their inherent environmental instability and heightened risk factors.

Attics experience dramatic temperature fluctuations, often reaching extreme highs in summer and extreme lows in winter, which directly stresses electronic components and material integrity.

Basements, conversely, frequently suffer from pervasive high humidity, presenting a significant risk of moisture damage, mold growth, and corrosion to circuit boards and metal parts.

Both locations also offer easier access for pests and are more prone to water damage from leaks or flooding.

While sometimes the only available spaces, their use necessitates extreme vigilance and robust protective measures, often involving sealed containers, desiccants, and frequent monitoring.

Ongoing Maintenance During Long-Term Storage

Implementing ongoing maintenance during long-term storage extends beyond initial preparation, ensuring the continuous preservation of the electronic drum pad’s condition.

This phase involves periodic checks and proactive measures designed to detect and address any emerging issues before they escalate into significant damage.

Consistent oversight reinforces the protective benefits of proper storage, safeguarding the instrument’s readiness for future use.

Periodic Inspection

Conducting periodic inspections represents a vital component of long-term storage maintenance, allowing for early detection and mitigation of potential issues affecting your electronic drum pad.

Even in seemingly ideal storage conditions, unforeseen environmental shifts or subtle material degradations can occur over extended periods.

Regular visual and tactile checks enable the owner to identify nascent problems such as moisture ingress, signs of pest activity, or physical deformities that might compromise the instrument’s integrity.

These inspections serve as a proactive safeguard against silent degradation.

Users should plan to inspect their stored electronic drum pad every few months, ideally once every three to six months.

During each inspection, carefully remove the drum pad from its protective case or container.

Visually examine all surfaces, including rubber pads, plastic casing, and metallic components, for any signs of discoloration, swelling, cracking, or unusual odors that could indicate mold growth or material degradation.

Pay close attention to ports and connectors for evidence of corrosion.

Look for any droppings, nests, or chewed marks that would suggest pest infestation.

If the drum pad is stored in a less-than-climate-controlled environment, an occasional brief airing out in a dry, room-temperature space can also be beneficial, allowing any trapped moisture to dissipate.

Prompt identification of issues during these inspections facilitates timely intervention, preventing minor problems from escalating into costly or irreversible damage to your valuable percussion instrument.

Airing Out (If Applicable)

Airing out your electronic drum pad periodically, especially in environments prone to humidity fluctuations or stagnant air, plays a crucial role in preventing moisture-related damage and maintaining material freshness.

Although proper sealing in a protective case offers significant defense, residual moisture or odors can sometimes become trapped within enclosed spaces over long periods.

Introducing fresh, dry air helps to dissipate any accumulated condensation, reduce the risk of mold or mildew growth, and refresh the materials, particularly rubber components that can benefit from occasional environmental exposure.

This practice involves briefly removing the electronic drum pad from its sealed container or gig bag and placing it in a well-ventilated, dry, and room-temperature area for a short duration, typically for an hour or two.

It is absolutely essential that the airing out environment itself is not excessively humid or dusty.

Avoid airing out the drum pad on a day with high outdoor humidity or in a location with direct sunlight, as these conditions could counteract the benefits.

This process proves particularly beneficial for electronic drum pads stored in slightly less than ideal conditions, such as closets without active climate control.

The brief exposure to ambient air helps to stabilize internal moisture levels and keeps the materials from developing a stale odor, contributing to the overall longevity and pleasantness of your musical equipment.

Testing Functionality (Before Re-use)

Testing the functionality of your electronic drum pad thoroughly before re-integrating it into your setup after long-term storage constitutes a critical final check, confirming its operational readiness and preventing potential issues during use.

This comprehensive test validates that all electronic components, sensors, and connections have withstood the storage period without degradation, ensuring the instrument performs as expected.

Skipping this step risks discovering malfunctions during a performance or recording session, which can be disruptive and frustrating.

| Component Group | Functionality Check | Expected Behavior | Troubleshooting Tip |

|---|---|---|---|

| Pads/Triggers | Strike each pad individually with a stick | Consistent sound output, accurate velocity response, no missed hits | Check cable connections, module settings; clean pad surfaces |

| Module Inputs | Plug in all previously used pads/cymbals | Module recognizes all connected pads, no “phantom” triggers | Verify cable integrity (no shorts), ensure snug connections |

| Audio Outputs | Connect to headphones/speakers; test each output (L/R, Aux) | Clear, unclipped sound from all active outputs | Check cable integrity, amplifier/speaker settings, module volume |

| MIDI Output | Connect to a MIDI interface/computer | MIDI messages sent for each hit (monitor with MIDI utility) | Verify MIDI cable, module MIDI settings, computer driver |

| Power Supply | Plug in power adapter | Consistent power, no flickering lights, no unusual hum | Inspect adapter for damage, ensure power outlet is working |

| Buttons/Knobs | Press all buttons, turn all knobs | Responsive, no sticking or erratic behavior | Gently clean around buttons/knobs (if necessary) |

The testing process should involve a systematic check of every interactive element.

Begin by carefully reconnecting the power supply and allowing the drum module to fully boot up.

Then, connect all percussion pads and electronic cymbals to their respective inputs on the drum module, ensuring each cable connection is firm and secure.

Systematically strike each pad and cymbal, listening for a clear and consistent sound output; pay attention to trigger sensitivity and velocity response.

Test all audio outputs (e.g., Main L/R, headphone jack, auxiliary outputs) by connecting to a speaker system or headphones.

If your electronic drum pad or module supports MIDI output, connect it to a computer or MIDI interface and verify that MIDI messages are being sent correctly for each hit.

Finally, operate all physical buttons, knobs, and faders on the drum module, ensuring they respond smoothly and predictably.

Any erratic behavior, missing sounds, or unresponsive controls indicate a potential issue that requires further investigation or professional servicing before the instrument is put back into regular use.

Tips for Re-integrating Your Drum Pad After Storage

Re-integrating your electronic drum pad after a period of long-term storage demands a thoughtful approach, focusing on gradual acclimation and thorough technical checks to ensure seamless functionality.

This careful process mitigates potential stress on components that have been dormant, guaranteeing the instrument performs optimally upon its return to active use.

Rushing the re-integration can lead to unexpected issues, undermining the benefits of careful storage.

Gradual Acclimation

Allowing your electronic drum pad to undergo gradual acclimation to its new environment is a crucial step if it was stored in a cooler or significantly different temperature zone.

Rapid changes in ambient temperature can induce thermal shock to sensitive electronic components, causing materials to expand or contract too quickly, which stresses solder joints, circuit board traces, and the overall structural integrity of the device.

This stress can lead to intermittent connections or even permanent damage, compromising the functionality of the percussion pads and the drum module.

Upon retrieval from storage, particularly from a cold environment like a basement or an unheated storage unit, place the electronic drum pad (still within its protective case or packaging) in the room where it will be used.

Allow it to sit undisturbed for several hours, or even a full day, enabling its internal and external temperatures to slowly equalize with the room’s ambient conditions.

This slow acclimation process minimizes internal condensation formation, which can occur when a cold object is introduced to warm, humid air, and prevents the mechanical stresses associated with rapid thermal expansion.

Only after the drum pad has completely reached room temperature should you unpackage it and proceed with power-up and testing.

This patient approach safeguards the delicate electronics and ensures stable performance from your musical equipment.

Careful Reassembly

Careful reassembly of your electronic drum pad after storage ensures all components are correctly seated and connected, preventing operational malfunctions and physical damage.

Rushing the reassembly process, or overlooking the precise placement of parts, often results in loose connections, misalignment, or even stripped screws, compromising the instrument’s performance and potentially leading to costly repairs.

This meticulous approach directly contributes to the stability and reliability of the electronic drum kit.

Users should systematically follow the disassembly steps in reverse, referring to their labeled cables and component bags as a guide.

When connecting percussion pads to the drum module, ensure each cable is firmly inserted into its correct port, checking for a secure click if applicable.

Avoid excessive force when tightening mounting clamps or inserting jacks, as this can strip threads or damage ports.

For any components that were fully detached (e.g., cymbal arms, module mounts), ensure all screws and fasteners are properly aligned and hand-tightened before applying a final, gentle turn with the appropriate tool.

Double-checking every connection and mechanical attachment before powering up the unit prevents issues like intermittent triggers, missing sounds, or unstable mounting.

This methodical reassembly process guarantees that your electronic drum pad is structurally sound and electronically ready for use.

Driver and Firmware Updates

Checking for and applying any necessary driver and firmware updates represents a crucial step before fully re-integrating your electronic drum pad after long-term storage, ensuring optimal performance and compatibility.

Manufacturers frequently release updates to enhance functionality, resolve bugs, improve trigger response, or ensure compatibility with newer operating systems or digital audio workstations (DAWs).

Neglecting these updates can lead to unforeseen glitches, sub-optimal performance, or even complete incompatibility with modern software environments, diminishing the overall user experience.

Upon retrieving your electronic drum pad and successfully reassembling it, connect the drum module to a computer (if applicable, via USB or MIDI).

Visit the manufacturer’s official website and navigate to the support or downloads section for your specific drum pad model.

Search for the latest firmware updates for the drum module and any necessary USB drivers or software applications.

Follow the manufacturer’s instructions precisely for the update process, which typically involves downloading a file and running an installer program.

Ensure your computer remains powered on and stable throughout the update to prevent bricking the device.

Applying these updates ensures your electronic drum pad operates with the latest enhancements and maintains seamless integration with contemporary musical software, maximizing its utility and keeping your musical equipment at its peak performance.

Conclusion

Proper long-term storage of an electronic drum pad transcends mere convenience; it constitutes an essential practice for safeguarding a significant musical investment and ensuring its sustained operational excellence.

From meticulous pre-storage preparations like thorough cleaning and battery removal, to the careful selection of an environmentally controlled storage location, every step contributes to the instrument’s longevity.

Ongoing vigilance through periodic inspections further guarantees its pristine condition, mitigating the risks of environmental degradation or component failure.

By adhering to the guidelines outlined in this comprehensive article, owners empower themselves to protect their sensitive percussion pads and drum module from physical damage, corrosion, and electronic malfunctions.

The commitment to proper storage not only preserves the instrument’s current value but also ensures its readiness for future creative endeavors, allowing drummers and producers to seamlessly resume their craft with a fully functional and reliable electronic drum kit.

This diligent approach ultimately maximizes the enjoyment and utility derived from owning a versatile piece of electronic musical equipment for many years to come.